The pressure is on when it comes to testing specialist accelerator parts at Science and Technology Facilities Council (STFC) – but not to worry, our experts have it in hand!

A high-pressure rinse (HPR) facility has been designed, built and commissioned at STFC’s Daresbury Laboratory, to treat cavities bound for international particle accelerator projects.

What are cavities and why do we test them?

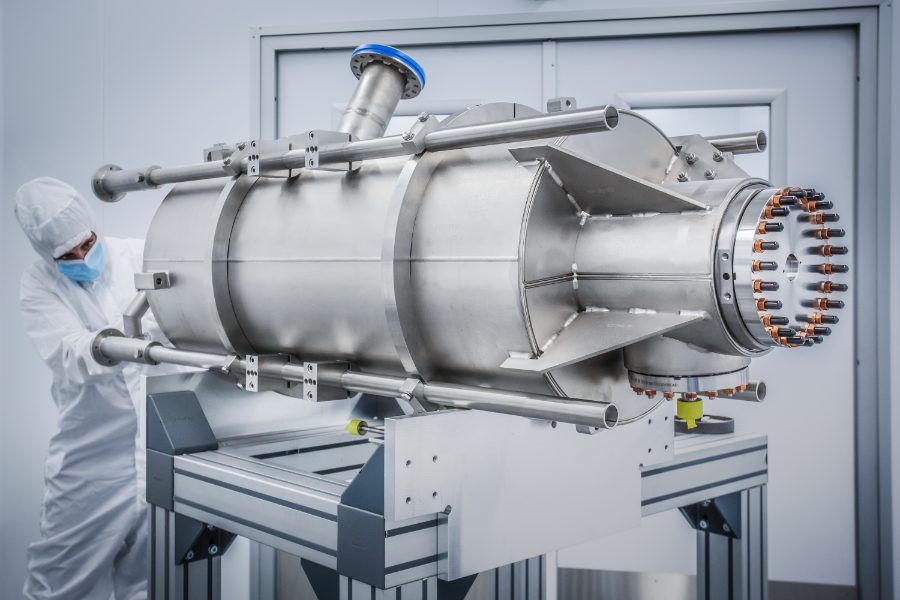

Cavities, in this case radiofrequency (RF) cavities, are structures through which particles are accelerated.

They are filled with radio frequency power and charged particles are added. The electromagnetic field creates an impulse which accelerates the particles. When in a superconducting state the charged particles can be accelerated using much less electrical power. Superconductivity is a property which allows certain materials to conduct electricity without energy loss when cooled below a critical temperature.

It is imperative that cavities are ultra clean leaving the manufacturing process, so they can reach their operating parameters while in a superconducting state. Even the slightest number of particles in a cavity can lead to a deterioration in cavity performance.

To ensure cavities meet their specifications, we test them in our bespoke vertical test facility to make sure that all cavities are fit for purpose for our end users.

Previous cavity testing projects have shown that as many as 50% of cavities can fail their first test due to field emission (radiation). There are many reasons this could happen: manufacturing residue, transportation, handling etc. But when it happens, we need to be equipped to recover them up to their specification before they are moved to the next phase for module integration and finally prepared to install them into the accelerator.

A member of the Daresbury Laboratory cavity test team inside the high pressure rinse facility. She is working on a superconducting cavity which is bound for the European Spallation Source. Credit: STFC

Working at the cav wash to recover cavities

For cavities which don’t meet specification, a HPR facility has been designed, installed and commissioned at the laboratory which enables a greater chance of recovery.

The HPR facility sits alongside the vertical test facility in the Superconducting Radio FrequencyLab – known onsite as the SuRF Lab.

Should a cavity fail to pass stringent testing, they are subject to a HPR of the radio frequency surface on the inside. There are a number of stages to this process, which have been validated and are controlled:

- A stage-by-stage cleaning process begins in an ISO 7 area (similar to hospital ward cleanliness) with specialist tooling which enables it to reach the ISO 4 main clean room (much like an operating theatre cleanliness).

- The ISO 4 cleanroom is where all the critical preparation takes place before the next step.

- It is loaded on to the HPR machine and subjected to a 12-hour cleaning cycle which utilises ultra-pure water at very high 100 bar pressure, where all processes have been validated to ensure that the cleaning process itself doesn’t introduce new contaminants.

- Finally, the cavity follows a reverse process through the cleanrooms to ensure it meets specification before being reloaded back on to the cavity support structure and retested.

A clean cavity is a happy cavity…and even happier accelerator

The first project to utilise the HPR facility was the in-kind contribution for the European Spallation Source (ESS) in Sweden, which has been using Daresbury Laboratory’s facility for high beta cavity testing and reprocessing. A key objective for the technical team was to ensure that all the cavities which came through the HPR workflow and testing process were not degraded.

To date for the ESS project, the team has made a significant impact on recovering cavities with our new facility. So far, they have rinsed 14 cavities with a 64% recovery rate – which is fantastic news for all those involved. Any cavities that fail to be recovered are further assessed for corrective action, such as chemical etching or more intrusive requirements undertaken by the industrial partner.

The combined testing and cleaning facility that we now offer gives a new capability to test that superconducting RF cavities are fit for purpose for an accelerator and to maximise the chance of recovery of a non-conforming cavity.

Mark Pendleton at Daresbury Laboratory, pictured within a cleanroom facility which is used for accelerator cavity testing. Credit: STFC

The project team is already planning changes to the facility to meet requirements for the next cavity testing project. Cavities destined for the Proton Improvement Plan II (PIP-II) project are due to start arriving at the canal-side site early in 2024. PIP-II cavities are a different size to those used in the ESS, so infrastructure changes will be made to accommodate them. Given the size, the HPR facility will be even more vital to the success of the project.