UK engineers have started producing a crucial element of an international flagship experiment that will allow scientists to answer fundamental questions about the Universe.

The Long Baseline Neutrino Facility (LBNF) at Fermilab near Chicago in the US will direct an intense pulsed beam of neutrinos to the Deep Underground Neutrino Experiment (DUNE) at South Dakota.

Results from the experiment:

- may indicate why the Universe is made of matter

- would detect a supernovae in our galaxy

- could observe proton decay.

The Science and Technology Facilities Council (STFC)’s Technology Department at the Rutherford Appleton Laboratory (RAL) at Oxfordshire is producing the target that will produce the neutrinos for LBNF.

Key element in a complex accelerator chain

Dr Chris Densham, the principal investigator for the project, said:

We have been funded to build what is perhaps the most critical link in a complex and powerful accelerator chain, the neutrino production target for LBNF at Fermilab.

A large international collaboration is relying on us to build a device that can convert the most intense pulsed proton beam in the world into a beam of neutrinos that can be detected some 800 miles away at the far detector, DUNE.

We are thrilled to have been entrusted with such a high-profile contribution to the LBNF/DUNE project.

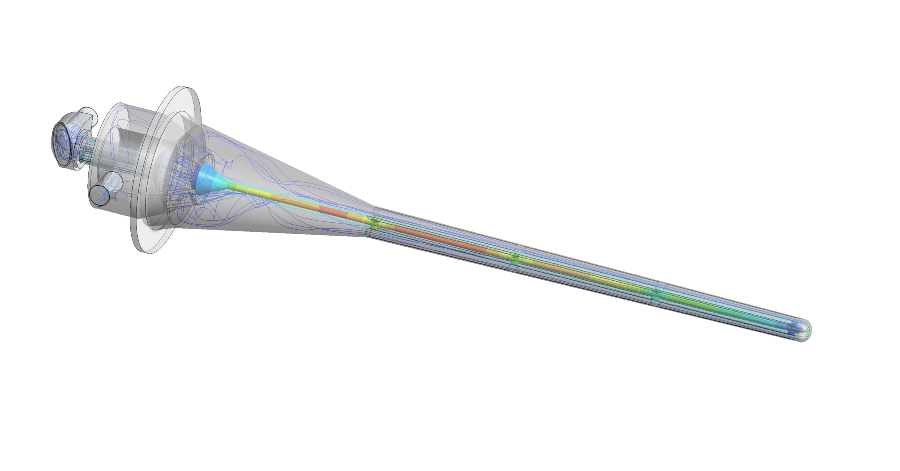

Computer simulation of helium coolant flowing through the LBNF target at up to 440 m/s, keeping the temperature of the graphite core to below 500°C. Credit: Dan Wilcox

Challenges with target production

In particle physics experiments, a target is like a crash pad for powerful proton beams.

After the protons strike the target, a particle shower is produced.

Some of the newly born particles decay or transform into neutrinos, whose extremely rare interactions with matter are then captured and analysed.

The target, in principle, is very simple, a graphite rod at least 1.5 metres long.

However, STFC engineers face several challenges to building a robust device that produces the highest possible flux of neutrinos:

- the target will have to handle the full intensity of a tightly focused, high-energy proton beam

- heat needs to be removed from the target using high velocity helium gas

- the target has to survive shock vibrations similar to being attached to a rocket and launched into space every second!

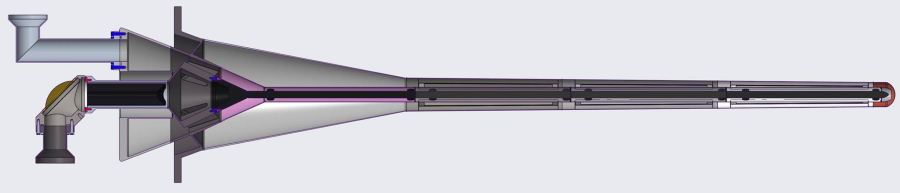

Cross section of the model of the neutrino target. Credit: Joe O’Dell

Designing and supplying key components

STFC’s Technology Department is designing and supplying key components of the target cooling system, and for the target itself, it is using nuclear grade graphite.

Most other materials would melt or disintegrate after a single beam pulse, with a temperature rise of around 100°C in 10 microseconds.

Another part of the project is to supply a remotely operable target exchange system that can replace the target’s highly radioactive components.

Ideally, the targets produced by STFC will have a lifetime of at least a year before they will need to be replaced.

International collaboration

To help achieve as long of a lifetime as possible, STFC engineers and Fermilab colleagues started an international collaboration, Radiation Damage In Accelerator Target Environments (RaDIATE). RaDIATE now has more than a dozen international institutes.

RaDIATE applies the expertise and facilities of nuclear materials scientists to the challenging environment faced by such components, with every atom along the beam centreline being displaced several times a year.

The current LBNF-UK target project follows a successful £1.5 million four-year design study carried out by the same team in the Technology Department of STFC’s RAL in Oxfordshire.

Phase 2 will now use the remaining £4.5 million allocation to deliver the target to the LBNF facility in March 2027.

Promoting UK manufacturing expertise

Peter Loveridge, the Phase 2 project manager, said:

This is a fantastic opportunity to showcase what we do at STFC, and to promote UK manufacturing expertise on the international stage.

With this funding announcement the whole team is super-motivated to see our cutting-edge designs transformed into real operational hardware.

Further information

About STFC’s contribution

In 2017, the UK government announced the investment of £65 million into LBNF and DUNE.

This is one of the three UK projects supported by this funding.

There are two other projects for the LBNF/DUNE experiment that the UK is involved in:

- Proton Improvement Plan-II at STFC’s Daresbury Laboratory

- the liquid argon DUNE detector, which involves a large collaboration of UK universities and includes the Anode Plane Assemblies (APA) factory also at Daresbury.

APAs will read out the tiny electrical signals of neutrino interactions with the liquid argon.

They are large and made of thousands of turns of wire, around 24 kilometres for each APA.

Daresbury Laboratory is challenged with the task of producing not one, but 150 APAs with millimetre precision.

Top image: 35-ton-capacity Prototype cryostat for LBNF/DUNE, Anode Plane Assemblies. Credit: Reidar Hahn/Fermilab