The textile industry is responsible for eight to 10% of the world’s carbon emissions, more than international flights and shipping combined.

Chemical dyes affect the health of textile workers, causing dermatitis, disorders of the central nervous system and even cancer. Untreated effluents from leather tanneries are discharged into waterways, causing a build-up of toxic sediments in rivers.

Reducing the environmental impact of the textile industry is a complicated problem, but a project led by SAGES, a startup that makes dyes from food waste, could play a role in its solution.

About the project

Working with Cranfield University, SAGES and Osmose (a design studio specialising in biodesign and mycelium materials) developed a mycelium leather dye using waste avocado pits to give a naturally tanned look.

SAGES co-founder and Director Emily Taylor said:

By focusing on waste streams, both for the dyes and the coating that’s applied after dyeing, we hope that the end product will form part of fashion’s shift from a linear model to a circular, waste-based one.

The leather alternative, developed by Osmose, is the first to use all natural materials throughout its production, as the company’s CEO and Creative Director Aurelie Fontan explained:

There are two alternatives to animal leather, neither of which are 100% natural. There are those that are purely synthetic, the material is synthetic, the colouring is synthetic. And then there are the plant-based ones, which often contain synthetic dyes or use plastic laminates to prevent stretching and provide protection against scuffing.

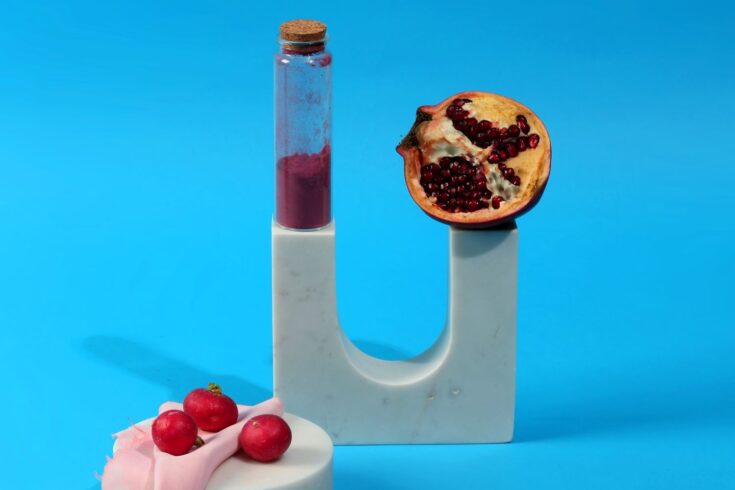

Vegetable dyes and vegetable sources. Credit: SAGES

The global bio-based leather market was valued at $647.21 million in 2021 and is expected to grow by 6.2% per year until 2030. Stricter animal welfare and environmental policies, as well as an increasing demand for sustainable products, are responsible for this growth.

An Innovate UK Smart Grant of £109,958 funded the collaborative research and development project.

Emily said:

It’s difficult as a startup because you’ve got to allocate your time and resources very carefully. So, I don’t see how we would have been able to achieve this project without Innovate UK funding. Cranfield University’s help was invaluable, too. Thanks to the funding and opportunity to collaborate with our project partners we have this prototype with real commercial potential.

As well as producing a world’s first all-natural mycelium leather-alternative prototype, the project has resulted in a new startup that will produce natural dyes for screen printing. Emily said:

That’s definitely come out of the growing relationship SAGES and Osmose have developed through working together on this project.

Top image: Dye derived from pomegranates. Credit: SAGES