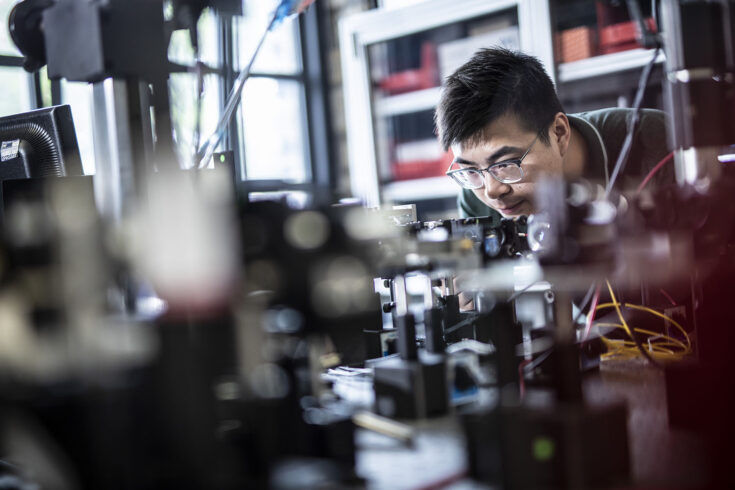

Precision manufacturing

The Engineering and Physical Sciences Research Council (EPSRC)-funded Centre for Precision Technologies (CPT) at University of Huddersfield develops next generation manufacturing metrology technologies.

Metrology is the scientific study of measurement. By employing effective metrology systems, users in fields like design, manufacturing and engineering can trust that their work is accurate and meets the standards to which they must adhere.

The CPT provides the latest measurement theory and technologies, underpinning zero waste and carbon neutral smart manufacturing growth and productivity.

In linking measurement and production together, the CPT is exploring how metrology research in machine tool technology, surface metrology, mathematics for metrology, instrumentation and precision manufacture could be linked to production to improve quality while minimising costs.

Credit: Centre for Precision Technologies at University of Huddersfield

It works with over 150 industrial partners, providing technology solutions for advanced measurement in manufacturing. Within the UK, product verification can be up to 20% of manufacturing cost, costing UK businesses around £15 billion each year.

Benefiting from the capabilities and experience of the CPT, the Centre for Innovative Manufacturing in Advanced Metrology (CIM) (2011 to 2017) and subsequent Future Advance Metrology Hub is enabling UK leadership in technologies critical for future manufacturing industry application.

This is a combined EPSRC investment of over £15 million in CIM and the hub, hosted and led by the CPT. It is enabling the University of Huddersfield to grow a significant national and international asset in the application of advanced metrology technologies.

Partnerships delivering impact

Led by Professor Dame Xiangqian (Jane) Jiang, the CIM’s achievements include the reduction of machine calibration times by 60 to 70%, increasing machining capability, reducing waste and improving product quality. Impacts from the research include:

- industry partner Rolls-Royce implementing the improvements in its UK plants, with further plans for its supply chains

- company Machine Tool Technologies taking the technologies further into industry, for example, BAE Systems and GKN Aerospace

The CPT has exclusive licencing agreements with:

- partner Dapatech Systems: developing technology that significantly reduces thermal errors on the types of machines used to produce many of the world electronics consumer goods such as smartphones, tablets and laptops

- Digital Surf: freeform surface characterisation technology widely used in UK industry for additive, laser processing and roll-to-roll manufacturing

- partner Renishaw: next generation advanced instrument technology is transferring into new metrology instruments

The research also contributed to the formation of spin-out company Wayland Additive, resulting in a £10 million venture funding injection. In 2020, Huddersfield-based Wayland Additive was only the second company worldwide to offer EBeam additive manufacturing capability. The company has signed a partnership agreement with HTL Co Japan Ltd which will see the latter operating as a distribution partner in Japan.

From CIM to hub

The Future Advance Metrology Hub builds upon the achievements of CIM. It is working with over 20 UK universities, Catapult Centres and the National Physical Laboratory through new research collaborations, secondments, feasibility projects, and hub to hub activities. Industry partners identify priority areas and hub academic partners respond with plans to address those priorities in collaboration with industry partners.

As well as helping to build a stronger and more influential UK metrology research community, it is also playing a leading role in the development of new industry standards. The hub has had £2.7 million worth of new commercial projects and consultancies with over 150 companies.

Recognised in prestigious awards

Long-term EPSRC-funded and Director of the Future Advance Metrology Hub, Dame Jane Jiang received her DBE in the 2017 Queen’s Birthday Honours. She was rewarded for her global reputation in metrology and her invaluable contribution to British-based engineering and advanced manufacturing.

The CPT was awarded the 2021 Queen’s Anniversary Prize for its innovative and ground-breaking research. The highest national honour for UK higher education, the award recognises outstanding work by UK universities that shows quality and innovation, and which delivers real benefit to the wider world.

Top image: Credit: Centre for Precision Technologies at University of Huddersfield