Among the barriers to widespread adoption of electric vehicles (EVs) is the time it takes to charge their batteries.

The public are used to driving cars whose sources of energy, their petrol or diesel tanks, go from empty to full in a matter of minutes. A lithium ion EV battery can take up to 12 hours to do the same.

Batteries with faster charging capabilities are seen by many as one of the solutions to this problem.

Moving towards electrification

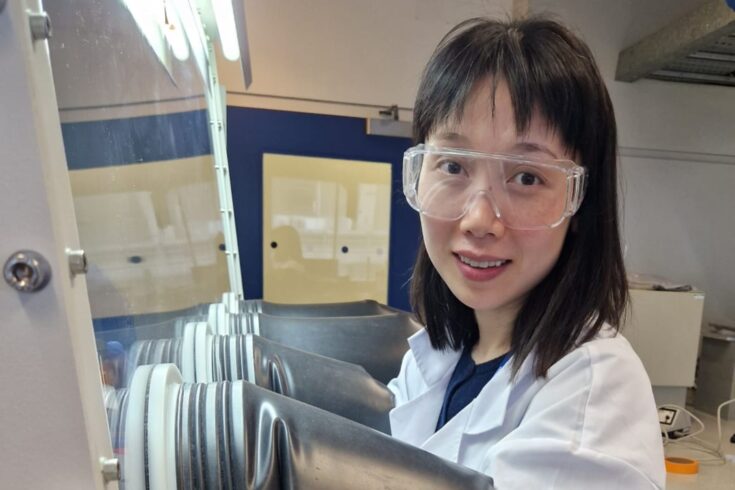

Dr Chun (Ann) Huang, Senior Lecturer in Energy Storage Materials at Imperial College London, is leading a project called Ion Diffusion in Electrochemical Energy Devices (INDEED).

The project aims to develop innovative, scalable ways to manufacture electrodes for fast-charging lithium ion batteries (LIBs) and next generation types of batteries as the world moves towards electrification. Examples of next generation batteries include solid-state batteries (SSBs) and sodium ion batteries (SIBs)

SSBs are safer than LIBs in theory as there is less risk of flammable electrolyte leakage and therefore fire. They are more energy dense when using a lithium metal anode, which is useful in keeping the weight of EVs down.

Reducing carbon emissions

INDEED is also investigating applying the developed manufacturing technologies to other types of electrochemical devices such as reversible solid oxide cells (RSOCs).

RSOCs generate hydrogen fuel from renewable energy and generate clean electrical energy in two modes.

They are useful in applications such as off-grid power generators and domestic combined heat and power, which can reduce carbon emissions by up to 30% compared to using a boiler for heat and a power station for electricity.

Sustainable and scalable

Ann said:

The conventional method of making electrodes is to make them with a random microstructure, which is not a very efficient use of the active materials in the electrodes. What I am doing is developing technologies to control the electrode microstructure to improve the utilisation of the active materials – and in a way that is sustainable and scalable.

UK Research and Innovation (UKRI) guaranteed the grant of £1,240,776 originally offered by the European Research Council so that Ann’s research, based at Imperial College London, could continue. The project started in June 2023 and will end in June 2028.

The project is an example of how the Horizon Europe guarantee fund is keeping pioneering scientists and their valuable research in the UK.

Research does not stop

Ann adds:

The guarantee funding reassures researchers like me that, while we are in a transition and there may be uncertainties, our research does not need to stop.

Ann is working with Imperial College London’s Industry Partnerships and Commercialisation team to patent the technologies and seek manufacturers who will use the technologies to make their own fast-charging batteries.

Top image: Credit: Dr Chun (Ann) Huang